Replacement of the Fort Nelson River Bridge

2014-2018 | Fort Nelson, British Columbia

When the BC Ministry of Transportation & Infrastructure built the Fort Nelson River Bridge in 1984 to support the natural gas, oil, forestry, and tourism industries, the project only had funding for the substructures (foundations and piers), so a temporary single-lane Acrow superstructure (steel truss with a timber deck) was installed on top.

Eventually, the superstructure was not meeting the needs of local traffic. Due to the single lane, vehicles had to queue up at either end of the bridge and wait to cross.

The Ministry retained McElhanney to design a permanent two-lane superstructure replacement and to retrofit the substructures. What made this project unique was the need to work with northern BC’s extreme weather conditions, an environmentally-sensitive river, pre-built substructures, and the need to maintain traffic during construction.

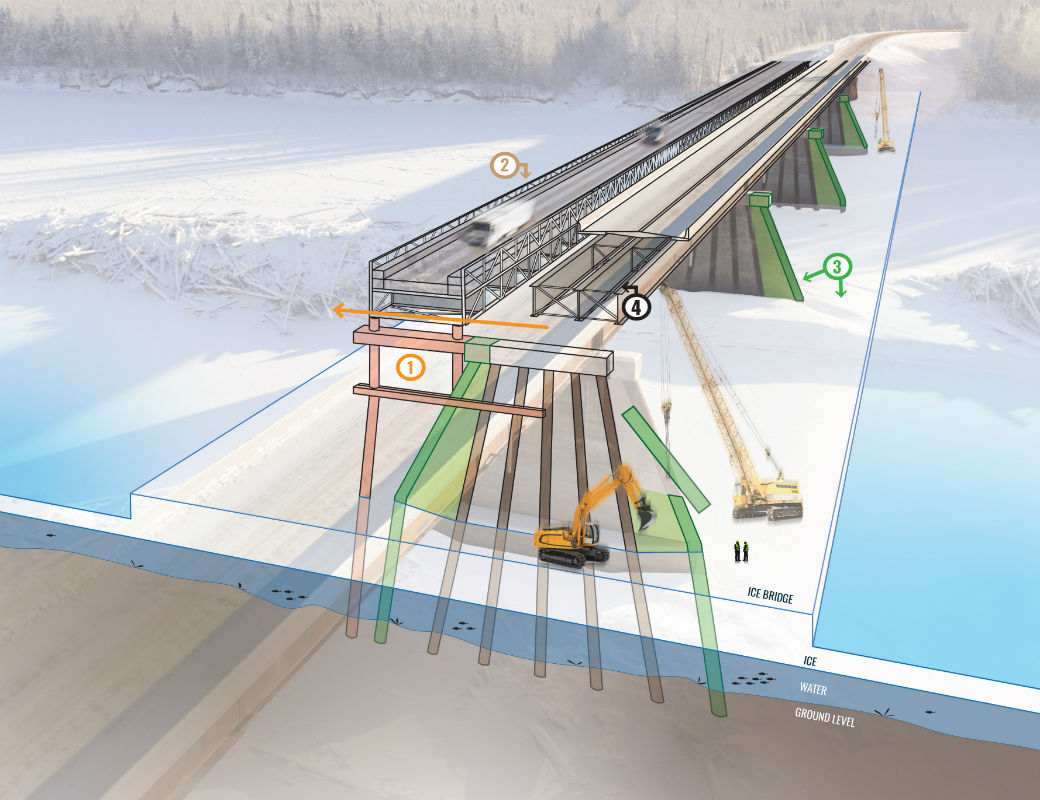

McElhanney developed the below innovative solutions:

- To maintain traffic flow, the contractor slid the existing superstructure 10.5m onto temporary pier extensions for use as a traffic detour;

- For the substructure piers retrofit, an ice bridge was used as a platform for workers to access the bridge;

- To ensure long-term durability, full superstructure continuity was provided over the bridge’s entire 430m length, protecting the steel girders.

Both lanes were opened to traffic in Fall 2017, and the new bridge accommodates increasingly heavy and large vehicle loads and improves the capacity and reliability of the highway.

McElhanney’s scope involved:

- Conceptual and detailed highway and bridge design;

- Substructure assessment and development of construction staging / superstructure replacement options;

- Strengthening design for substructures;

- Geotechnical engineering for land piers and liaison with the Ministry’s geotechnical engineer for river piers;

- Assisting in utility relocation;

- Assisting in public consultation;

- Preparation of tender documents;

- Engineering services during construction.

In 2019, the project received an Award of Merit from the Association of Consulting Engineering Companies – British Columbia.

The replacement and rehabilitation of the bridge was funded as part of BC’s provincial initiative On the Move, which contributed approximately $19.6M, and by the Canadian federal government’s New Building Canada Plan, which contributed approximately $15.4M